Sensors and Metrology – Data is the currency of our networked world. To gather this valuable commodity, more and more objects are being kitted out with sensors. The performance of measuring instruments is continuously improving at the same time, despite them often being no larger than a pinhead.

Sensor technology and metrology play a key role in all current technological megatrends to do with digitalisation. “Digital innovations are penetrating almost every aspect of our lives, changing the way we work and communicate, and facilitating new products and services. One thing they all have in common is reliance on data gathered and evaluated by sensors,” says Dr Andreas Schütze, Professor for Measurement Science and Technology at Saarland University and foreman of the jury for the innovation award of the German AMA Association for Sensors and Measurement. And innovations keep propelling this sector onwards. More and more new companies are being founded, new materials researched, and new technologies used.

Miniaturisation, digitalisation and versatility – sensor technology

It is essentially possible to identify three key trends in this area. Miniaturisation is the first of these. In an increasingly interconnected world, almost every device is expected to gather information on its own surroundings and application. This requires sensors that deliver high performance while occupying minimal space in the respective device thanks to their tiny dimensions. All this while consuming as little power as possible.

The digitalisation of the sensors themselves is the second key trend. Increasingly smart sensors not only gather data. They also evaluate it instantly before sending only the results to superordinate systems or the cloud.

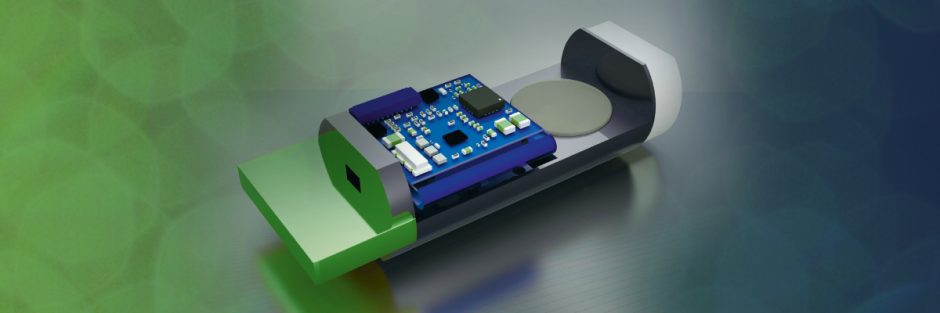

Sensor fusion is the third important trend. Smart objects in the Internet of Things require multi-sensors that can perform multiple types of measurement. And all of this at once while occupying the smallest possible amount of space.

Pooled data in metrology

Nowadays, there are a few examples of such multi-sensors, including Jumo’s plastoSENS variants. Here, sensor systems for a range of measured variables like temperature, moisture, pressure or force all fit into one plastic casing as a modular system. Through energy harvesting, the modules supply themselves with energy. The sensor signals are transmitted wirelessly through a Bluetooth interface. Sensors that gather and process data instantly and on-the-spot go one step further. Such systems are already in use today, especially in image sensors. Data are processed rapidly at their point of creation with only the strictly required information being extracted. In terms of using cloud services, this enables energy consumption, communication costs and latency times when transferring data to be reduced while also satisfying data-protection specifications.

Small and sensitive

MEMS in particular are synonymous with the miniaturisation of sensors. They have internal silicon structures, which are many times thinner than a human hair. So they can convert microscopically small movements into electrical signals, process these as information and then transmit them elsewhere. In a sense, this makes them the sensory organs of the technical world. They measure pressure, acceleration, rotation rates, moisture levels and much more besides.

Bosch expects that hundreds of billions of MEMS elements will be required in the future for all kinds of applications. Alongside the vast IoT domain, these also include automated driving, where MEMS sensors enable a vehicle to localise itself using only information on acceleration and rotation rates.

Such automated driving requires an especially large array of sensors. Time-of-Flight (ToF) sensors are an important building blocks in this set-up. They determine the distance from an object by measuring the time it takes for an emitted light signal to bounce back. Lidar systems operate in accordance with this principle. ToF solutions are now available as small, integrated modules. With a size of just eight cubic millimetres, they fit effortlessly into a smartphone. Where they make the phone camera’s auto-focus precisely adapt to the object or person being photographed. With a price tag of under three dollars, they also appeal to a number of other consumer applications. Such as rapid collision detection and avoidance in robotic vacuum cleaners or presence detection for notebook computers.

Pocket-sized spectroscopy

The latest technologies related to optical sensors are systems that measure the spectrum of an emitted and reflected ray of light. Previously, conducting this type of spectrographic analysis required a dedicated laboratory. Although corresponding solutions based on ultra-thin infrared chips with high detection capability are now available.

These include the Broadcom’s Qmini and Qwave series of compact spectrometers that combine state-of-the-art optical and electronic components to achieve very high performance spectroscopy measurements of ultraviolet (UV), visible (VIS), and near-infrared (NIR) light, covering ranges between 190 nm and 1100 nm in a small form factor. Based on the Czerny-Turner configuration do not require internal moving parts, avoiding any possibility of optical misalignment. This ensures reliable and stable long term performance.

Such affordable spectrometers are perfectly suitable for integrating into high-volume applications, and for various real-life applications such as process control and monitoring, biomedical applications, chemical research, environmental analysis, medical and pharma applications, forensic analysis, Raman spectroscopy, and many more.

There are also integrated spectral sensors offered by AMS and supported by EBV Elektronik. They enable new applications like color picking/matching, authentication, color and spectral analysis of materials and fluids detecting ingredients and compositions in industrial raw materials, agricultural products or foodstuffs for quality assurance “on the go”. High-level integration with advanced CMOS filter technology allows lifetime calibration accuracy and enables instrument makers to bring laboratory-grade precision to the field.