Autonomous farm vehicles will change the landscape of farming, allowing arable land to be used more efficiently while protecting the environment.

Agriculture is facing major challenges. The world’s available agricultural land will need to be used more efficiently to continue to feed its rapidly growing population in the future. Yet farms in many parts of the world today are lacking labour.

Autonomous farm vehicles: In Use 24/7

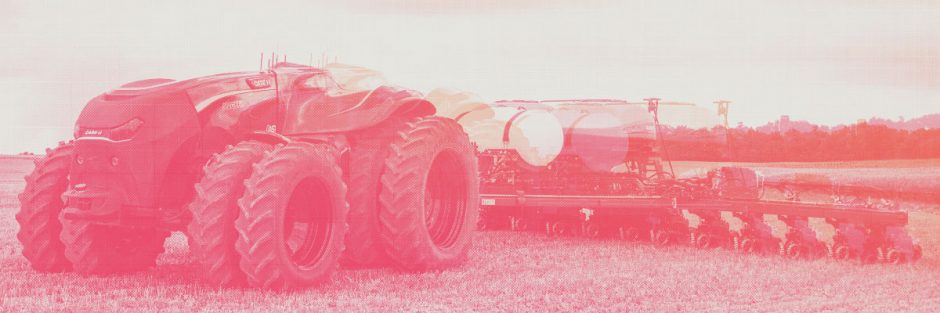

The major tractor manufacturers have therefore been working for several years on autonomous farm vehicles. For example, Case IH presented its Autonomous Concept Vehicle (ACV) to the public for the first time in 2016. “The ACV retains much of the conventional technology of a modern tractor, and uses ultra-accurate RTK GPS to provide parallel steering capability with a variation of less than 2.5 cm, which many farmers are already using to ensure missed or overlapped land between passes spans no more than this width,” Case IH’s Dan Stuart states. In addition, the ACV is equipped with radar, lidar, proximity sensors, as well as safety and wireless systems, meaning that it can be monitored and controlled from a PC or tablet. Consequently, having entered the field, the tractor can work completely independently without a driver. The ACV is still a concept. However, a test programme working with farmers in real-life conditions has already been launched.

To the Heart of Agriculture

However, in recent times, there has been a growing number of voices responding negatively to the use of large, heavy machinery on farms. Dr Jens-Karl Wegener, Head of the Institute for Application Techniques at Germany’s Federal Research Centre for Cultivated Plants, the Julius Kühn Institute, points out that “agriculture, the way it currently operates, is coming under social criticism. In the face of nitrate pollution, loss of species and soil compaction, we have to critically question how much longer it will be good for.” The use of ever larger machines on ever larger areas of land seems to be part of the problem rather than a solution. Wegener takes a different approach based on the needs of the individual plant.

“This sort of precision farming, geared to the needs of the individual plant, would naturally also affect how the land will look in the future,” project team member Lisa-Marie Urso says. Spot farming is the term she and her colleagues use for the new cultivation system, which takes account of small-scale differences in the landscape. “The benefit of spot farming would be the ability to achieve multiple crop rotations at a time, not only one, as has been the case to date,” Urso continues. Depending on the ground conditions, various crops (rape, wheat and beets) could be sown, taking into account properties of the land such as dips containing pooled water, dry hillocks or other small structures. “That would certainly increase the diversity of species in the fields, as well as saving on fertiliser and pesticides based on single-crop treatment,” Wegener comments.

Increasing intelligence thanks to machine learning

The fact that this is not merely a vision was demonstrated by start-up company Deepfield Robotics back in 2015 with its “Bonirob”, a robot the size of a small car which uses video and lidar positioning as well as satellites to navigate around the field with centimetre-precise accuracy. It is able to distinguish crops from weeds based on their leaf shapes, and removes weeds mechanically using a ramrod rather than with toxic herbicides. Any unwanted weeds are simply rammed into the ground at high speed.

In view of the diverse flora, the Bonirob’s automatic image recognition is key. Professor Dr Amos Albert, Head of Deepfield Robotics, describes the challenge: “The leaves of carrots and camellias are very similar in their early stages, for example.” So the Bonirob has to be taught how to learn and identify leaf shapes. Albert and his team apply machine learning for the purpose. The system captures large numbers of images, in which the Bosch researchers mark the weeds. “In this way, the Bonirob gradually learns to distinguish productive crops from weeds ever more efficiently based on parameters such as leaf colour, shape and size,” Albert explains. But the Bonirob is not yet available on the market as a production vehicle.

Tackling individual weeds in a targeted way

Swiss company Ecorobotix has gone one step further: it has already built an initial production run of its “Jät” robot. The test-phase machines are currently proving their worth on fields in Switzerland, France and Belgium. They are scheduled for official market launch in 2018. The solar-powered robot weighs just 130 kilograms. It works for as long as 12 hours a day with no human operator, and is controlled and configured entirely using a smartphone app. The robot orientates and positions itself using its RTK GPS, its camera and sensors. Its imaging system enables it to align itself to the rows of crops and to detect whether and where there are weeds within or between the rows. It adapts its speed to the density of the weeds as it does so. Two robotic arms target a micro-dose spray of herbicide specifically onto the detected weed.