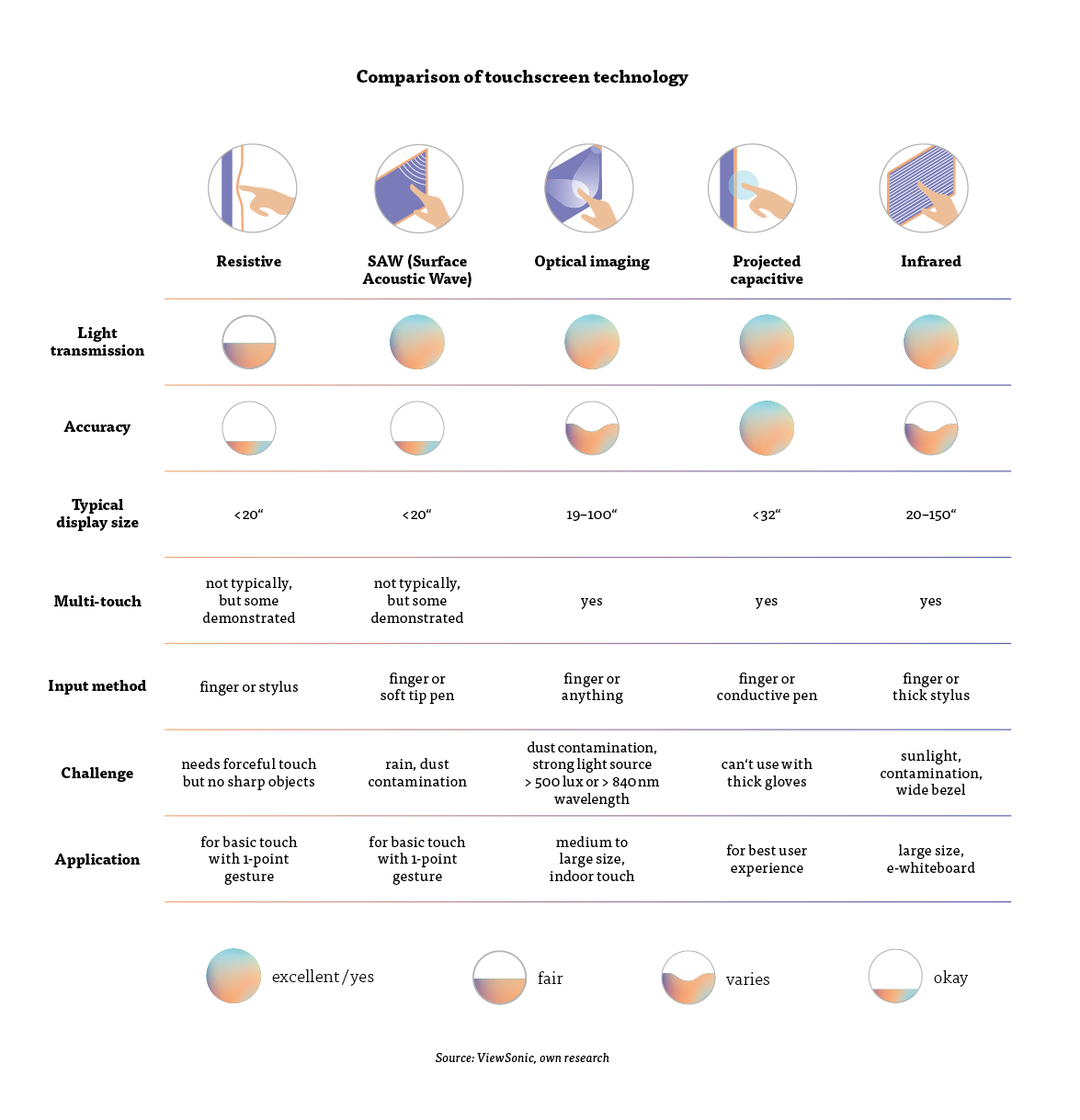

From smartphones to machine tools, operating devices by touch has become commonplace today. The type of technology that is used is determined by the application.

Touch-sensitive displays as Human Machine Interfaces have long become a firm part of our everyday lives. Anyone using a smartphone is utilising touch technology. In shopping centres, touchscreens help people find information about products or stores. Many functions in cars are controlled via touch displays. In factories, touchscreens allow employees to easily access information and intuitively operate even the most complex systems. According to a report published by Spherical Insights & Consulting, the global touchscreen display market is expected to grow from 65.60 billion US dollars in 2021 to 163.10 billion US dollars by 2030. The proliferation of touchscreen displays can in part be attributed to the superior intuitiveness of graphical user interfaces compared to traditional input devices such as a mouse or keyboard. The possible input options are predefined for the user by the system and can be varied depending on the task or user. This simplifies operation, thus saving time and reducing input errors. All sorts of technologies are used to detect touch, but they can be broadly classified into five fundamental systems.

Operation by pressure

Resistive touchscreens react to pressure. They are constructed from two transparent conductive layers separated by an overlay. As soon as a user touches the screen, the two layers deform and come into contact, causing electricity to flow. A controller detects the electrical voltage difference and can determine the position of the input from this.

Resistive displays can be operated with a finger, stylus or gloves. They are also resistant to foreign bodies and moisture. However, the light transmission is lower than with other technologies due to the layers of film, and the mechanical deformation reduces their lifespan.

Response to capacitance change

A significantly longer lifespan and higher brilliance are offered by projected capacitive touch technology (PCAP). Micro-fine wires are incorporated into the glass surface of the screen and voltage is applied in order to create a capacitive field. When a conductive object – for example, a finger – is placed on the surface, this field changes. The touch controller can thus detect and evaluate the touch. PCAP technology offers precise touch detection and fast response times. However, it cannot be operated with a glove, and PCAP displays are typically only produced up to 32 inches.

Detection by infrared

Much larger touchscreens – up to 150 inches – are enabled by infrared touch technology. Infrared LEDs are arranged along the frame of the display, and each LED has a corresponding photodetector on the opposite side. This creates a grid of invisible infrared light beams. The input can be determined by interrupting individual light beams, for example with a finger. This means that infrared touch panels can also be operated with gloves, offer good light transmission and are relatively long-lasting. However, glare can negatively affect the user experience.

Optical imaging

Also suitable for large screens is optical touchscreen technology. Optical sensors register a touch as soon as the line of sight is blocked by any object. Light transmission and image sharpness are generally good with this solution, as no additional layers are applied to the display itself. Optical touchscreens are considered one of the simplest and most cost-effective touch solutions, although the resolution of touch detection depends on the number and type of optical sensors installed.

“Hearing” touch

SAW technology (Surface Acoustic Wave) also belongs to the touch solutions. Piezoelectric transmitters on the surface generate an invisible grid of ultrasonic waves, which are collected by receivers. Touching partially interrupts these waves, enabling accurate determination of the finger’s position. SAW technology offers high contrast and colour accuracy, a robust design, and enables IP certification.

Anticipating touch

Recent advancements have made it possible to anticipate which part of the screen the user intends to touch and to execute the control step without actual physical contact. Jaguar Land Rover and the University of Cambridge have developed a corresponding solution called “predictive touch”. It uses artificial intelligence and sensors to recognise the user’s intended input target early on, which significantly accelerates the interaction.

Touch-sensitive surfaces

Touch detection is not only possible on displays. Capacitive touch operation or operation via strain gauges can also be used under thin sheets. These types of solutions are particularly suitable for premium products, such as those found in the domestic appliance sector, and for hygiene-sensitive areas – for example in a medical technology environment.