Critical raw materials such as cobalt, lithium, and rare earth elements are essential for the various technologies of the All Electric Society. To secure supply and reduce dependencies, the European Union enacted the Critical Raw Materials Act in spring 2024.

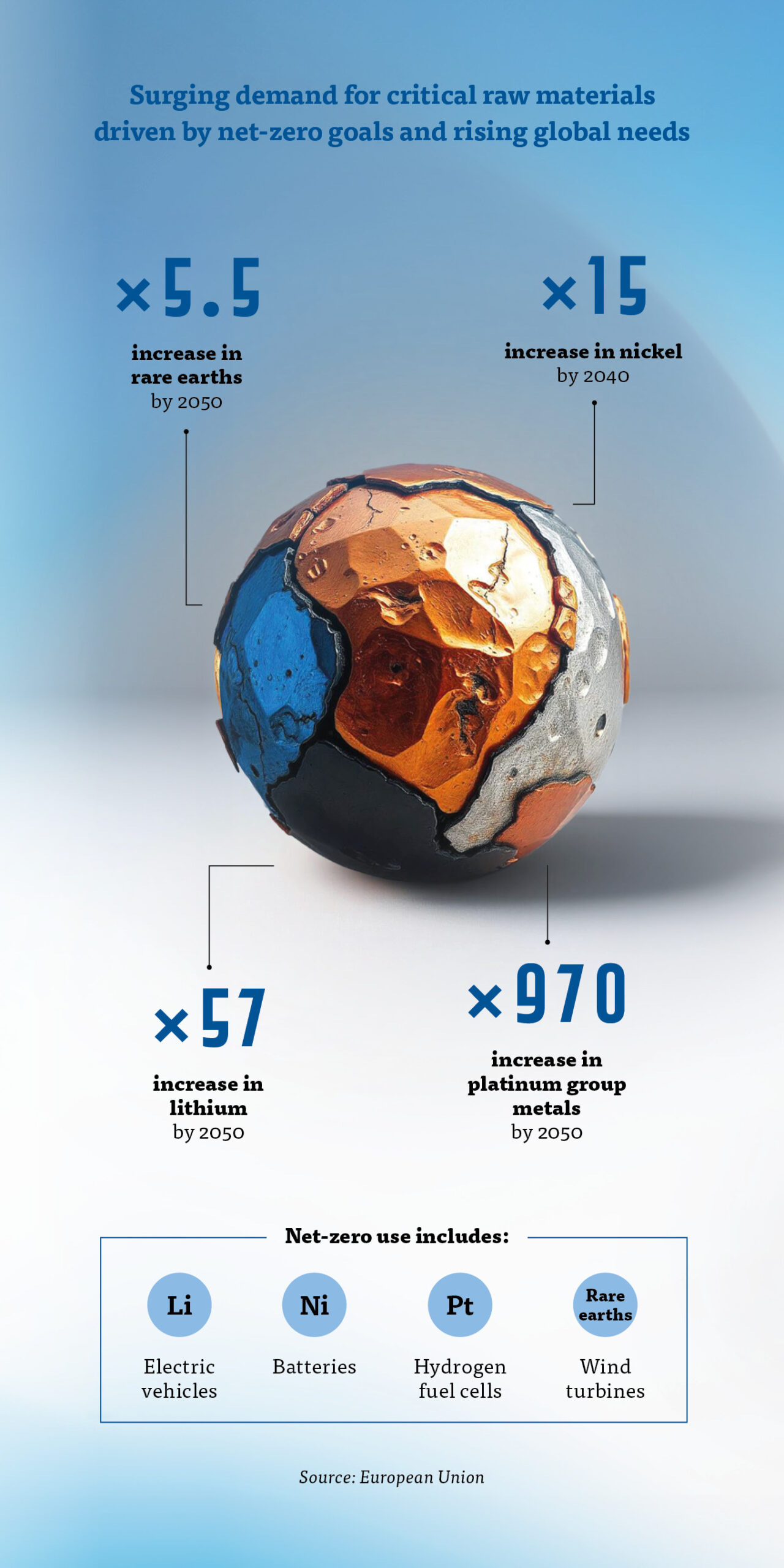

By 2050, the global demand for cobalt and lithium for electric vehicle batteries is expected to increase nearly twentyfold. The transition to a fossil fuel-free energy supply will require significant amounts of copper, aluminium, and iron, with demand likely to double. Rare earth elements, essential for technologies like wind turbines, will also be needed in much larger quantities.

“While the global economy will become less resource-intensive overall due to decarbonisation as it moves away from coal, oil, and gas,” says Felix Creutzig, head of the Land Use, Infrastructure, and Transport working group at the Mercator Research Institute on Global Commons and Climate Change (MCC) in Berlin, “the additional material requirements due to the climate transition, the associated resource extraction, and the resulting waste streams pose significant ecological and social risks at regional and local levels.”

Creutzig is the lead author of a study that explores the anticipated increases in material consumption due to the climate transition and suggests ways to mitigate them. The study highlights the importance of demand-side climate solutions, such as changes in mobility, housing, and diet, as well as the expansion of material recycling in the economy.

EU aims to Secure Raw Material Supply

Even with efforts to reduce demand, the realisation of an All Electric Society will not be possible without a secure supply of critical raw materials. To address this, the European Union introduced the Critical Raw Materials Act, a regulation designed to ensure a diversified, secure, and sustainable supply of critical raw materials for the EU’s industry. The regulation came into force in May 2024 and aims to strengthen supply within the EU and reduce dependence on individual suppliers. This is crucial because the market for critical raw materials is often dominated by a few supplier countries, which may not always be reliable. For example, Guinea accounts for nearly a quarter of global bauxite production (a precursor to aluminium), while half of the world’s cobalt reserves are located in conflict-stricken Congo. Additionally, 90 percent of semiconductor wafers for solar cells are produced in China.

From Extraction to Recycling

The Critical Raw Materials Act introduces benchmarks for increasing capacities in mining, processing, and recycling within the EU. These include simplified approval procedures and easier access to financial resources. A key aspect that the new EU regulation aims to improve is the recycling of critical raw materials. End-of-life products from the automotive industry, electric vehicles, e-waste, and decarbonised energy technologies are rapidly emerging as secondary sources of valuable critical materials. Market analysts from IDTechEx predict that by 2045, critical materials worth 110 billion US dollars will be recovered annually from secondary sources, with a total weight of over 3.3 million tonnes. The Critical Raw Materials Act sets recycling targets for various materials.

Call for more Flexibility

However, rigid, static targets, such as those currently outlined in the Critical Raw Materials Act, have been criticised by experts. Raw material markets and supply systems are inherently highly dynamic – fixed targets may not be effective. New technologies can quickly increase demand for certain raw materials, while substitution effects can rapidly reduce the demand for others that were previously considered scarce and critical. For example, cobalt: strong substitution effects in batteries are already emerging. Will cobalt still be needed as a key cathode material for lithium-ion batteries by 2030, given the future state of technology?

Professor Simon Glöser-Chahoud, an economist from the TU Bergakademie Freiberg, states, “For successful regulation of raw material supply, both the set quotas and the list of strategic raw materials must be regularly reviewed and adjusted.”