Printed electronics merge the two worlds of printing and electronics manufacturing. The results are bendable, flexible electronic circuits which can be mass-produced very cheaply – ideal for the wearables market.

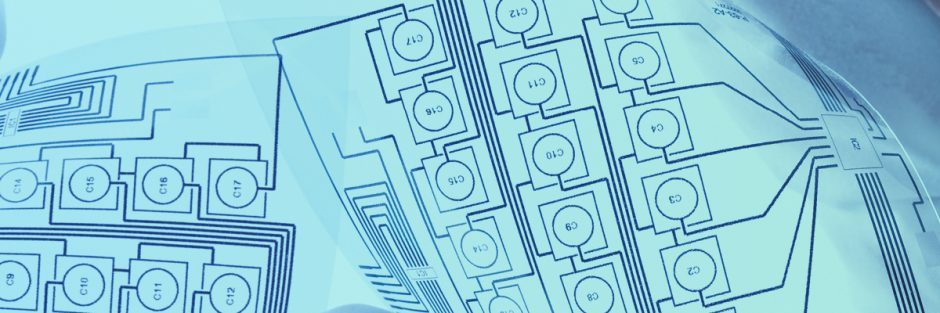

Portable electronics are to be found in watches, fitness gadgets, clothing featuring sensors, and in many other things that have to be light, thin and flexible. Conventional silicon-technology-based electronics are constrained in meeting those requirements, however, because the circuit boards are rigid. By contrast, organic semiconductor materials enable electronic components to be printed onto flexible films by conventional techniques such as screen or offset printing. In this process, instead of graphic printing ink, conductive, semiconducting, dielectric and insulating materials are printed over each other in layers. This technology already enables cost-effective production of circuits with up to 100 transistors today.

Wearables market is an opportunity

Printed electronics are less powerful than conventional silicon technology, but much cheaper to produce. “Flexible electronic components enable the creation of comfortable and adaptable portable devices which fit seamlessly into everyday life,” says Tony Sun, an analyst with Lux Research. The market research organisation has analysed registered patents relating to wearables and printed electronics to determine how far the trend towards portable devices is driving flexible electronics. But Sun discovered that little research in the field of printed electronics is targeted at wearable technology: “The lack of overlap between patents relating to printed, flexible and organic electronics and those relating to wearables indicates the necessity – and the opportunity – to develop and apply those technologies specifically for portable electronic devices.” Nowadays, hybrid solutions are increasingly being applied in the wearables sector: combining the benefits of printed organic electronics with conventional silicon technology. On the bracelet by Polyera, for example, which in its entirety consists of a flexible display, the sensors are printed electronics while the processors are conventional silicon.

Not only printable, but also compostable

Student scientists at the Karlsruhe Institute of Technology (KIT) are concerned, however, that printed electronics might be promoting the throw-away trend, by cutting production costs and opening up new markets with disposable products such as smart sticking plasters. That is why they have been researching into printed electronics made from compostable natural materials – with chips and dyes made from plant extracts, or insulators from gelatine. “They are not as durable as the inorganic alternatives, but they withstand the life-cycle of disposable electronics without causing harm,” says Dr Gerado Hernandez-Sosa, Head of the “Biolight” Student Research Group. Moreover, at the end of their useful lives, the electronic devices can simply be placed in the organic waste bin, or on a compost heap, where they will rot away just like a banana skin.

This is not yet true of commonly used printed electronics, such as organic light-emitting diodes (OLEDs), even if the name implies otherwise. “By ‘organic’ we mean all carbon-based plastics. The term itself is no indicator of eco-friendliness,” explains Dr Hernandez-Sosa. For example, the carrier films of OLEDs – the equivalent of paper for electronic inks – are made of the same plastic as conventional beverage bottles. The Biolight group uses only materials that actually occur in nature for the purpose. Suitable carrier film materials include starch, cellulose or chitin. The student scientists use almost no metals or metalloids, such as silicon, at all. The advantage of plastic: it is flexible, cheap and can be processed into mile-long print films. This technology makes it possible to produce food labelling with electronic traffic light indicators of use-by dates, for example, or plasters with built-in sensors which monitor the healing process, on an industrial scale.

(Picture credits: Fotolia: Shawn Hempel)