Nature is like a library providing the best ideas taken from life – often, these can be applied to technical product development. Plants and animals are thus increasingly becoming models for new smart technologies.

Nature presents researchers and developers with a wealth of ideas for innovative Smart Systems. Not only can they find fantastic functional and design principles here, but also blueprints for efficient usage of resources. So it comes as no surprise that almost all large global players have their own bionics department. Bionics is the science of the interface between the fields of biology and technology, which detects solutions that have existed in nature for millions of years, endeavouring to transform these into modern, sustainable, resource-saving, highly efficient technical innovations.

Only the beginning

“I think the biggest innovations of the 21st century will be at the intersection of biology and technology. A new era is beginning,” said Apple founder Steve Jobs. Pioneering inventions of recent years, inspired by natural materials, plants and animals, prove him right. However, bionics is only at the beginning. Out of the 30 million species existing on Earth, only about 100 have been investigated for technical purposes. Each species can deliver exciting ideas for new products, which can be implemented in various industries today due to innovative materials and powerful microelectronics.

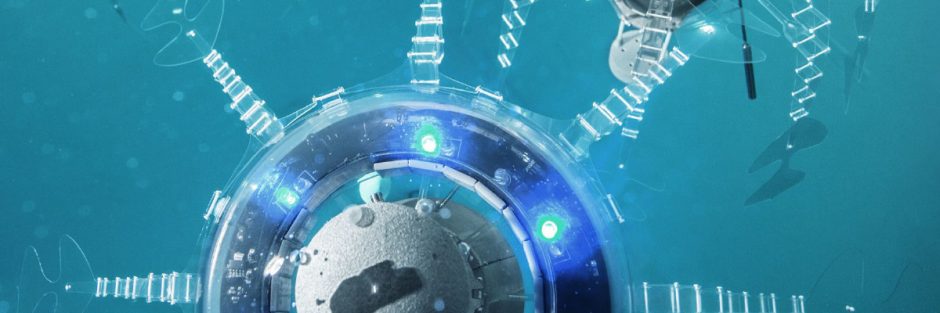

Collective behaviour of artificial jellyfish

One example is AquaJellies from Festo – artificial, autonomous jellyfish with electrical drives and intelligent, adaptive mechanics. Based on its state, each jellyfish decides autonomously which action to perform. “Their integrated communication and sensor technology as well as real-time diagnosis enable coordinated, collective behaviour even with limited space,” explains Dr Elias Maria Knubben, head of Corporate Bionic Projects at Festo. “Festo visualises potentials and ideas with these bionic technology carriers about how efficient systems might look in future in the field of water technology. Process monitoring and condition monitoring are important topics for all systems in the process industry and consequently water technology.” This principle of adaptable and collective behaviour can be applied to automation. Here it means that many decentralised intelligent systems work together, thus solving large tasks of small systems that act together in a targeted way.

Self-repairing robot

Researchers at the Intelligent Systems and Robotics Institute at the French National Center for Scientific Research (CNRS) and the research lab in computer sciences in Lorraine and their applications have been inspired by nature: for the purpose of robot programming, they imitate the ability of animals to automatically adapt to injuries or handicaps. Similar to a dog, which quickly learns to walk on three legs, robots are expected to compensate for damage. The robot stores possible movements in this case and the attainable performance in a matrix in order to perform its tasks. If the robot is damaged, it uses a special algorithm, which is based on the information stored in the matrix. It uses this algorithm to run through the different motion sequences and to determine which would be best to compensate for the damage. For example, if it is not able to only walk on its hind legs, next it will try to just use its front legs. What is surprising here is how quickly the robot reacts. In less than two minutes it has learned a new type of movement. This new technology paves the way for the development of more efficient and stable autonomous robots, for example as paramedics.

The eye as a model

But nature also serves as a model for very concrete and new electronic systems: for example, Fraunhofer researchers have developed an innovative 3D laser scanner with time-of-flight measurement methods. Based on the model of the human eye, it can focus on key image sections in order to capture these with respectively higher resolution. Efficient software algorithms analyse a quickly captured 3D overview image and guide the scanner (the “attentiveness” of the system) to interesting image sections, so that these can be scanned with high resolution – in accordance with the fovea of the human eye, which makes sure that we can see small sections of an overview image clearly. This makes it possible for the first time to gain situational high-quality 3D information within a short time. The extremely high scan speed of 1.6 kHz of the Fraunhofer scanner enables scans practically in realtime and thus also the capturing of moving objects like aeroplanes on landing strips or vehicles on building sites.

(picture credits: Festo AG & Co.KG)