A car-maker in China is co-ordinating the production of different engine variants with the aid of RFID. By doing so, it has made its production a zero-defect operation, with complete transparency throughout.

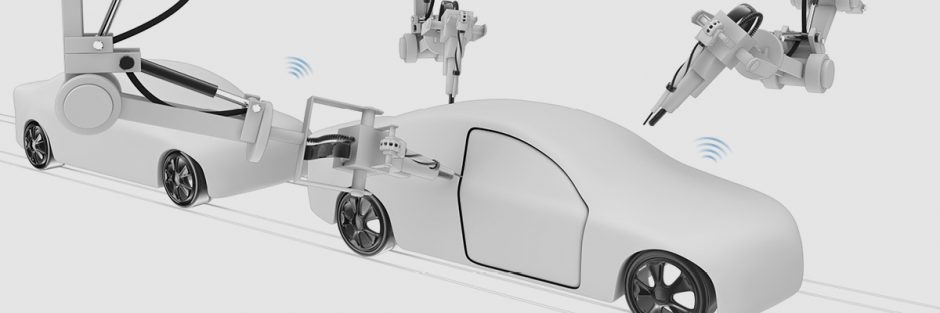

A Chinese car-maker produces multiple engine variants on one line. To ensure that the right components for the various engines are fitted during the assembly process, the company employs RFID technology.

RFID chip ensures the right allocation

To achieve this, the pallets carrying the engine blocks were fitted out with RFID tags from Turck. The production line RFID system identifies the specific engine variant based on the tags. Then the components required for that variant are read from a database and linked to the engine, so telling the system which components have to be fitted in the specific engine.

Based on that information, workers then retrieve the required components from a buffer stock. A light signal indicates the storage location from which they need to retrieve the parts for the engine in question. Small parts are sorted into special boxes. A worker brings the boxes to the production line, where they are stacked in racks and transported on a conveyor belt from station to station together with the engine blocks, with each engine being allocated a rack carrying the components needed for the specific variant. Each rack also bears an RFID tag, while large engine components have their own tags. This ensures that a component can be unambiguously allocated to the right engine.

Production data is stored

The ability to store data on the RFID tags is also utilised. The engine block tags, for example, carry test values and measurement data collected from the production line stations which are cross-checked against the specifications stored in the database. The 8 kilobyte memory on each tag also holds the engine and component identification numbers, as well as additional information. That data is available for statistical evaluation, for quality assurance, and to ensure complete transparency throughout the production process – including beyond the shipping date. This provides the car-maker with comprehensive statistical data on its production, enabling it to identify cumulating defects and their sources, and so eliminate them.

(picture credits: Shutterstock)