Energy efficiency is often referred to as the “first fuel” for a clean energy transition, as it allows for the quickest and most cost-effective reductions in CO2 emissions. In the All Electric Society, the focus is particularly on electricity conversion, with power electronics playing a central role.

Being mindful of energy use pays off, as the cheapest and most climate-friendly kilowatt-hour is the one that isn’t consumed at all. Achieving high energy efficiency is crucial to avoid unnecessary energy losses. Energy efficiency refers to the ratio of energy input to its useful output. Over the past years and decades, many efforts have been made to waste less energy, such as through more efficient LED lighting, improved vehicle fuel efficiency, and advancements in industrial processes. The Intergovernmental Panel on Climate Change (IPCC) estimates that implementing all options to increase energy efficiency could save more than five gigatonnes of CO2 equivalents by 2030.

“Energy efficiency has many additional benefits. It improves air quality, helps businesses save energy so they can reinvest savings into other productive areas, and promotes more efficient industrial processes,” says EU Commissioner Kadri Simson.

Global Energy Efficiency increases

Since 2020, global investments in energy efficiency have risen by 45 percent according to the IEA. For example, nearly all countries now have efficiency standards for air conditioning, and the number of countries with standards for more efficient industrial motors has tripled over the last decade. However, the global improvement in energy intensity – the amount of energy required to produce a unit of gross domestic product (GDP) – has slowed. In 2023, it improved by only 1.3 percent, well below the rate needed to achieve climate targets.

“The world’s climate ambitions hinge on our ability to make the global energy system much more efficient. If governments want to keep the 1.5 °C goal within reach while supporting energy security, doubling energy efficiency progress this decade is critical,” said IEA Executive Director Fatih Birol.

National examples show that it can be done differently. For instance, the European Union improved its energy intensity by eight percent in 2022 and by five percent in 2023. The United States achieved a four percent improvement in 2023.

Reducing Conversion Losses

In the All Electric Society, efforts are mainly focused on the more efficient use of electricity. A crucial lever in this regard is reducing losses during the conversion of electrical energy. When electricity is converted in terms of voltage form (direct or alternating current), voltage level, current, and frequency, losses inevitably occur. Static and dynamic conduction losses in the semiconductor materials of power electronics increase switching losses during the provision, distribution, and use of electrical energy, thus increasing the consumption of valuable primary energy. In Europe alone, an estimated three terawatt-hours of electrical energy are wasted annually due to conversion losses – a figure that is rising. To achieve significant energy savings, improvements must start with the semiconductor materials themselves.

Increasing Efficiency with SiC and GaN

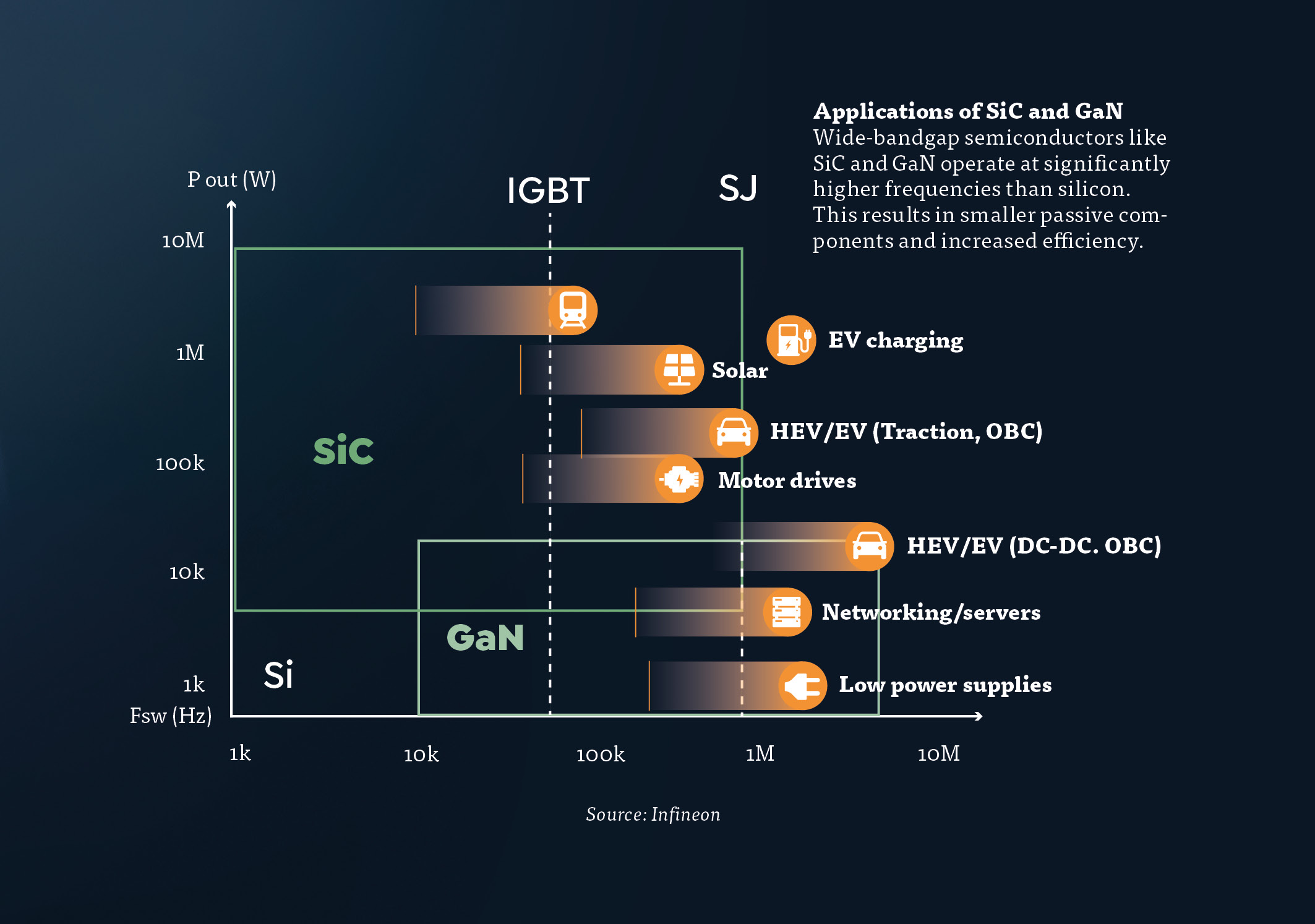

The silicon components currently established in power electronics are being replaced by more powerful semiconductors with wide bandgaps (WBG), which have superior physical and electrical properties. Semiconductor materials such as silicon carbide (SiC) and gallium nitride (GaN) offer higher switching speeds and better thermal properties. SiC is particularly in demand for high-power applications like electric vehicles and industrial motors, while GaN excels in low-voltage applications such as fast chargers for consumer products. Overall, both semiconductor materials enable significantly higher efficiencies in power conversion: in typical applications like power supply modules or inverters, efficiency improvements of three to five percent can be achieved.

Future with Ultra-Wide Bandgap (UWBG) Semiconductors

It is already foreseeable that in the future, even WBG components will be surpassed by semiconductors with ultra-wide bandgaps (UWBG). A promising UWBG semiconductor is aluminium nitride (AlN). Compared to established silicon components, AlN/GaN transistors, which have already been successfully manufactured on AlN wafers in research projects, exhibit up to three thousand times lower conduction losses and are about ten times more powerful than SiC components.