For a long time, Moore’s law controlled the requirements when it came to developing new microchips. But new technology trends, such as the Internet of Things and Artificial Intelligence, are posing new challenges for the semiconductor industry. At the same time, miniaturising chip patterns is increasingly coming up against its limits.

Ever since semiconductor technology has been around, customer requirements have generally not changed much – microchips should be ever better, faster and cheaper. And the semiconductor industry has indeed made great advances in the development of its semiconductor products. It has consistently continued implementing Moore’s law, according to which the number of ICs on a microchip doubles every two years. Smaller chips with densely packed transistors enable smaller, more powerful electronic devices to be produced at lower prices. A comparison often cited in the industry illustrates this progress very clearly: if the automotive industry had achieved similar performance improvements in the last 30 years, then a Rolls-Royce would cost just 40 dollars and be able to travel round the earth eight times with one gallon of petrol – with a top speed of 2.4 million miles per hour.

More Moore or More Than Moore?

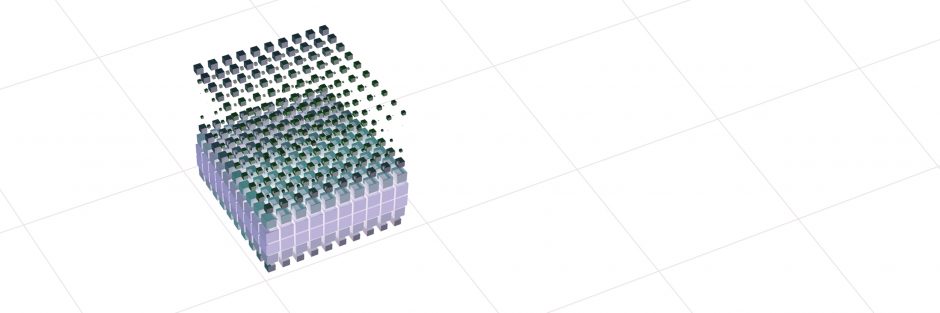

The development of semiconductors is increasingly coming up against the limits of Moore’s law. Nowadays, the patterns on the chips are getting close to an atomic scale and cannot be reduced further. One solution is a 3D approach. Here, layers of transistors are stacked on top of each other. This means the number of components per square millimetre can be further increased, even if the physical area dimensions cannot be reduced any more. Manufacturers could also layer different semiconductor materials over each other in the process, for example, by applying a layer made from compound semiconductors such as indium gallium arsenide on a layer with conventional silicon transistors. They can assume special tasks such as particularly fast signal enhancement or detecting light. Many experts see an alternative continuation of Moore’s law in integrating additional functions in the chips in this way. Instead of “More Moore” (further miniaturisation), their motto is rather “More than Moore” (combining digital and non-digital functions on the same chip). These types of solutions can already be found today in many components, such as in microelectromechanical systems (MEMS) or in radio frequency and analog/mixed-signal technologies (RF/AMS).

New solutions for AI applications

Many innovations in the semiconductor industry have been started by two higher-level technological trends: artificial intelligence and the Internet of Things.

AI is posing completely new challenges for semiconductor technology as the data volumes processed and stored in the process are huge. Improved semiconductor architecture is required to manage these. This process is less about improving the overall performance or computing power, but more about accelerating the data transfer out of and into the memory, as well as more efficient memory systems. Because of this, special neural chips have been developed which work like the synapses of the human brain. Instead of constantly sending signals, they only work when required. Furthermore, AI chips process data in numerous parallel processes, not in a sequence like previous processors. Alongside this, nonvolatile memories are increasingly being used in AI semiconductors. They can also store data without a constant power supply. Combining these nonvolatile memories with AI processors on a “system-on-a-chip” provides a solution for the requirements posed by modern AI applications.

Microchips in the Internet of Things

The Internet of Things is based on small-scale microprocessors built into various objects and which communicate wirelessly. Integrated sensors enable these mini-computers to detect and monitor their environment, process the data they capture, and share it with other objects or the Internet.

This requires microcontrollers which integrate sensors, processors, memories, Wi-Fi capability, microelectromechanical systems and a range of analog and digital circuits on a limited space. At the same time, the electricity consumption should be as low as possible as the (mostly mobile) objects cannot be connected to an electricity grid or it would be too expensive and time consuming to replace the battery frequently. For example, at the moment, there are considerations about replacing the base material silicon, which is generally used in integrated circuits today, with a new semiconductor material such as gallium arsenide.

As many IoT devices must also withstand harsh environmental conditions, there are high requirements in terms of the robustness of the semiconductor products, for example when it comes to resistance to vibration, temperature, water and/or salt.

High performance for 5G

The IoT will only be able to realise its full potential with the new mobile radio standard 5G, however. With a high bandwidth and transmission quality, along with low latency, in many areas 5G is the technical basis for the next step in the development of the IoT. Here, a solution is provided by radio frequency and power electronics based on gallium nitride (GaN) or silicon carbide (SiC). These so-called wide-bandgap semiconductors (WBG) are characterised by considerably higher energy efficiency, for example.

Energy-efficient power electronics

WBG semiconductors for power electronics can be manufactured ten times smaller than conventional silicon semiconductors, and they lose up to 50 per cent less heat. Furthermore, transistors made from WBG semiconductors can increase the switching frequency compared to silicon transistors by up to 500 per cent. Thanks to these properties, SiC and GaN semiconductors can meet increasing customer requirements in many applications – from electromobility to photovoltaic inverters, right up to fast chargers.